Remnant Plate Generation

| NOTE: This is an optional advanced module and needs to be licensed separately.

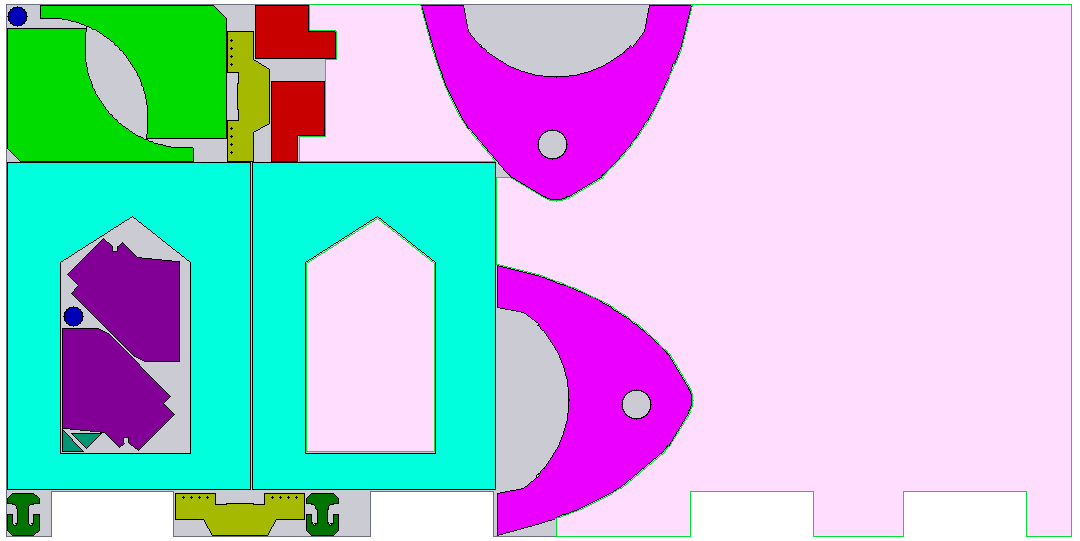

Depending upon the nature of the parts and sheets, some area in the sheet is left un-utilized. If the information about the un-utilized area is provided to the user, then user can use the same again for nesting the parts. This un-utilized area that can be used by the user again is called remnant plate. The shape of the remnant desired is depends mainly on the type of the material and the cost incurred and the expectations vary from customer to customer. Hence, options to select the type of remnant is provided to the user. Remnant plate generation module generates following type of remnants depending on the criteria set by the user. Key Features:

Benefits:

A typical remnant plate generated when different options are selected is shown below:

The remnant generation module in NestLib provides a facility to the user to automatically generate the remnant plates once a sheet is nested. These remnant plates can be stored in the inventory database and can be queried for nesting purposes before using a fresh sheet. |

Quick Links |