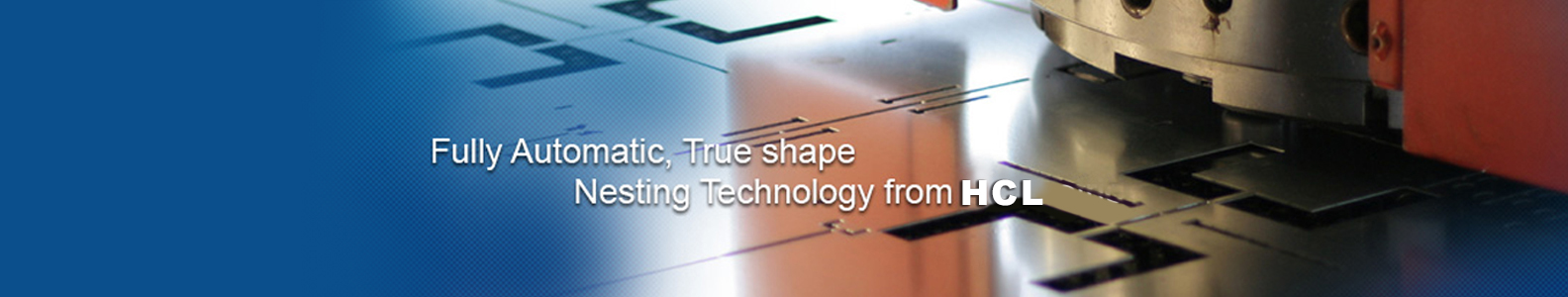

Making cost-effective designs has become a basic requirement in manufacturing, and proper nesting can contribute to this overall goal. Cost reduction seems to be today’s mantra in the manufacturing community. All aspects of a design that can result in cost are scrutinized, and measures are taken to prevent those unwanted and costly elements from making […]

Read More…Design Parts as Near Rectangle as Possible – An Assembly Example

An electrical cabinet design was originally designed with two parts as shown below. The assembly contains a T-shaped non-rectangular part. To improve nesting quality, T-shaped part is redesigned into two near rectangular parts. This simple redesign improves material utilization and hence scrap area (Gray shaded) is less and remnant area is more (Pink shaded) as […]

Read More…Design your Components for Maximum Material Utilization

Material cost governs a major share of product cost in sheet metal products and hence it is advisable to design parts/assemblies for maximum material utilization. All opportunities which can result in improved material utilization have to be analyzed. An interesting case is shown in Fig 1 which gave an utilization of only 39.58% with the […]

Read More…Redesign Your Components for Cost Reduction

A work table design modeled as shown below ended up with a nested layout involving lot of scrap. Fig 1: Original design Fig 2: Nested layout of the original design By suitably redesigning the work table as shown below, part utilization increased from 4 part nesting to 6 part nesting in the same sheet and […]

Read More…Methods and Issues in Determining Material Cost for Sheet Metal Parts

Cost of a sheet metal part comprises three major cost components such as material cost, processing cost and overheads. Determining accurate material cost has always been an issue. Theoretically material cost can be calculated as follows: Material Cost = Area of the flat pattern * thickness * (weight per unit volume) * cost per unit […]

Read More…