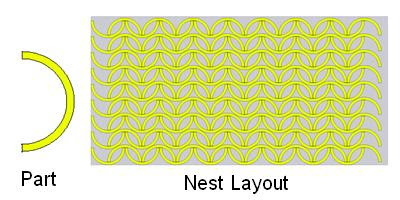

Material cost governs a major share of product cost in sheet metal products and hence it is advisable to design parts/assemblies for maximum material utilization. All opportunities which can result in improved material utilization have to be analyzed. An interesting case is shown in Fig 1 which gave an utilization of only 39.58% with the original design.

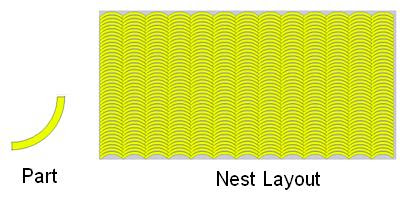

To improve the material utilization, the part was redesigned into two pieces as shown in Fig 2, which can be welded together to form the original design. This redesign improved the material utilization to 75.03%. Though utilization of material couldn’t be improved further due to design limitations, redesign helped to generate 273 pairs of redesigned model compared to 144 numbers of original models from the same sheet size. Welding is an additional process introduced by redesign but it was found that cost of material saving is greater than the additional welding and cutting costs.

Visit Nestlib website for more details.

Visit Nestlib website for more details.